คุณยังไม่มีสินค้าในรถเข็น

เครื่องบากเหล็กแผ่นอัตโนมัติ OMCA art. 930 Reverse

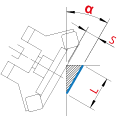

Machine a reverse downside chamfer with an angle of 0° to 60°, or a square edge condition a plate up to 100 mm thick at an automatic feed speed of up to 1.4 meters/minute.

Motor Power

230/400 Volt, 3 Phase

5,5KW.( 5500W) 50/60 HZ

Bevel Length

max 59 mm

Bevel Angle

0° – 60°

Plate Thickness

8 – 60 mm (*) 8 – 100 mm

Feeding Speed

0 -1.4 mt/min

สถานะของสินค้า : สินค้าพร้อมส่ง

0 บาท

- Frame in steel and aluminium casting;

- Hardened work plate with sliding rollers;

- Motorized feeding with two polyurethane wheels (90 shore);

- Trolley complete with height adjustment devices, chips protection, chip box, and swivel wheels with brake;

- Possibility to work with the trolley lifted in the presence of irregular floor;

- Possibility to work also without trolley.

| ART. 930 Reverse | |

|---|---|

| Motor power | Three-phase 230/400 Volt, 4kw, 50/60 Hz, 4 pols |

| Chamfering adjustment | From 0 mm to 33 mm (53 mm diagonal) |

| Chamfering angle | From 0° to 60° |

| Plate thickness | From 8 mm to 60 mm |

| Cutter | Ø 63 mm – height 40 mm – hole 22 mm |

| Cutter speed | 800 RPM |

| Chamfering speed | From 0 to 1,2 mt/min |

| Working height | 820 mm ÷ 970 mm |

| Working direction | Clockwise |

| Dimensions | 600 x 600 x h 1550 mm |

| Applications | Steel, stainless steel, cast iron, aluminum, titanium alloys, hardox, super duplex, etc… |

| Weight | Kg. 205 |

| Packing dimension | mm 1150 x 830 x 1550 h – Kg. 240 |

(*) Different voltages available

Cutter

| Sketch | |

| Diameter | Ø 63 mm H=40 mm Ø=22 mm (1x) |

| Insert | ISO SDHT1204 12,7 x 12,7 Thickness 4,76 mm |

| N° | 5 |

| Material | WIDIA |

| Insert code | 02045018 |

| Option | Coated 02045018/R For light alloy |

Bevelling performances

|

MAX ACHIEVABLE CHAMFER AT FIRST STEP

|

|||||||||||||||||||||

|

MAX ACHIEVABLE CHAMFER

|

|||||||||||||||||||||

Special versions

- Plate thickness 8/100 mm;

- Plate thickness less than 8 mm ;

- Cutter speed variator.

| แบรนด์ | โอมก้า |